https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

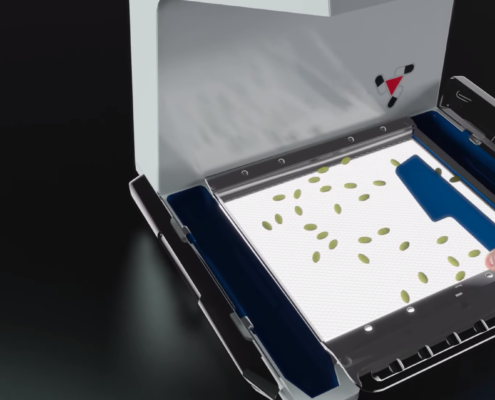

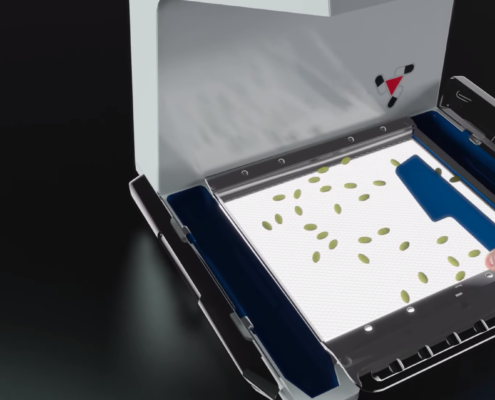

AbstraktMarketing2025-08-14 17:55:532026-01-28 21:13:24How Automated Bottle Count Verification Systems Improve Line Efficiency

https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-01-28 21:13:24How Automated Bottle Count Verification Systems Improve Line EfficiencyHow to Increase Pharmaceutical Bottle Filling Speed and Accuracy

In the pharmaceutical industry, the efficient and accurate filling of bottles with medications is crucial for the safety of patients and the success of operations. Pharmaceutical bottle filling needs to meet stringent regulatory standards and plays a vital role in ensuring that the right dosage reaches the patient, in the right packaging, and at the right time. Increasing the speed and accuracy of pharmaceutical bottle filling is essential for staying competitive and meeting market demand.

This blog explores various strategies and technologies that enhance the speed and accuracy of pharmaceutical bottle filling processes.

The Importance of Speed and Accuracy in Pharmaceutical Bottle Filling

Before diving into strategies for improvement, it’s essential to understand the significance of speed and accuracy in pharmaceutical bottle filling:

- Compliance With Regulations: The pharmaceutical industry is governed by strict regulatory standards, including Good Manufacturing Practices (GMP) set by regulatory bodies like the FDA and EMA. Accuracy in filling ensures that the correct amount of medication is dispensed, preventing over or under-dosage, which can be dangerous.

- Operational Efficiency: Faster filling processes translate to increased throughput, enabling pharmaceutical manufacturers to meet growing market demands. Improved efficiency also reduces labor costs and minimizes the risk of downtime during production.

- Customer Satisfaction: Product labeling, dosage, and packaging accuracy leads to higher customer satisfaction. Errors in pharmaceutical filling can lead to recalls, damaged reputations, and potential legal liabilities.

Different Ways to Increase Pharmaceutical Bottle Filling Speed and Accuracy

Pharmaceutical manufacturers must implement strategies and technologies that enhance the speed and accuracy of their bottle-filling processes.

Below are a few ways you can boost pharmaceutical bottle filling speed and accuracy:

Implement Advanced Filling Technologies

One of the most effective ways to increase the speed and accuracy of pharmaceutical bottle filling is by adopting advanced filling technologies. Over the years, numerous innovations have been introduced in filling equipment that offers faster, more precise results.

Below are some key technologies to consider:

Servo-Driven Filling Machines

Servo-driven filling machines are equipped with advanced motors that can be programmed to provide exact control over the filling process. These machines are highly accurate and can fill bottles faster than traditional pneumatic machines. They use precise feedback systems to adjust filling volumes in real time, ensuring consistency across large batches.

Peristaltic Pumps

Peristaltic or tube pumps offer accuracy when filling liquids into bottles. These pumps work by moving liquids through flexible tubing, reducing the risk of contamination since the liquid never comes into contact with the pump’s internal mechanisms. Peristaltic pumps are ideal for high-precision pharmaceutical applications, such as when filling delicate liquids, vaccines, or other bioactive ingredients.

Inline Checkweighing

Inline check weighing systems are integrated into the filling process to ensure that each bottle contains the correct amount of product. These systems can detect any underfill or overfill issues in real time and reject bottles that do not meet the specified weight. With this system, pharmaceutical manufacturers can immediately detect discrepancies, reduce waste, and maintain compliance with regulations.

Automated Bottle Capping and Labeling

Incorporating automated capping and labeling systems into the filling process ensures that the filled bottles are sealed correctly and labeled with the correct product information, reducing human error and speeding up the entire process. Pharmaceutical packaging automation can improve throughput while maintaining accuracy and reducing contamination risks.

Learn about the most common pharmaceutical product packaging mistakes and how to avoid them.

Optimize Bottle Filling Line Layout

The layout and organization of the filling line can significantly impact the speed and accuracy of pharmaceutical bottle filling. Proper organization minimizes bottlenecks, reduces downtime, and ensures smoother operations.

Here’s how to optimize your filling line:

Streamline Workflow

A well-organized workflow ensures that each process step, from filling to capping to labeling, is as efficient as possible. Create a logical sequence of operations so that there’s minimal movement or downtime between stages. For example, filling stations should be located near capping stations to avoid unnecessary bottle transportation.

Eliminate Downtime

Downtime can significantly reduce the overall efficiency of the filling process. Regular maintenance and monitoring of machinery can help ensure equipment operates without interruption. Scheduled downtime for maintenance or upgrades can be strategically planned during low-demand periods to avoid disrupting high-priority production runs.

Modular Systems

Modular filling systems allow for easy scalability, meaning additional units can be added to increase speed when necessary. Modular equipment makes it easier to perform maintenance or adjustments on one line section without impacting the entire system. This flexibility helps ensure that production continues smoothly.

Enhance Employee Training and Engagement

A highly trained workforce ensures speed and accuracy in pharmaceutical bottle filling. While automation can take care of much of the filling process, employees still play an essential role in overseeing operations and ensuring everything runs smoothly.

Regular Training Programs

Ensure employees are well-versed in operating, troubleshooting, and maintaining the filling equipment. Regular training on the latest technologies and procedures will help employees stay up-to-date on best practices. It also reduces human error, which can directly impact speed and accuracy.

Quality Control Awareness

Employees should be trained on filling procedures and the importance of quality control. Emphasizing the role of quality checks will encourage operators to be vigilant when monitoring the filling process and spot discrepancies before they lead to product waste or safety issues.

Cross-Functional Collaboration

Collaboration between different teams (e.g., production, quality assurance, and maintenance) ensures a holistic approach to process improvement. When teams communicate effectively, any potential issues or improvements can be addressed proactively.

Incorporate Real-Time Monitoring and Analytics

Another effective way to improve speed and accuracy is by incorporating real-time monitoring and analytics into the filling process. Advanced data analytics can provide actionable insights to enhance performance.

Predictive Maintenance

Real-time data monitoring allows for predictive maintenance of filling equipment. Sensors can detect potential issues by analyzing machine data before they cause failures. For example, vibrations or temperature changes in the filling machine might indicate wear and tear, which can be addressed before the machine breaks down. This proactive approach prevents downtime and ensures the equipment functions at peak performance.

Batch Tracking

Batch tracking technology enables operators to monitor every batch of product that moves through the filling line. Tracking key parameters such as fill volume, batch number, and fill rate ensures that discrepancies are immediately detected and corrected. This reduces errors and ensures that each batch meets the required standards.

Statistical Process Control (SPC)

SPC tools allow for continuous monitoring and adjustment of filling parameters in real time. By analyzing data trends, manufacturers can identify patterns or deviations from the desired process and make adjustments accordingly. This improves the accuracy of each fill and ensures that products are consistent across large production runs.

Upgrade to Fully Integrated Systems

A fully integrated system that combines filling, capping, labeling, and packaging into one streamlined process offers several advantages. Integration’s key benefits include faster operation, fewer human touchpoints, and reduced risk of errors.

Automated Material Handling

Integrating automated material handling systems like conveyors can speed up the movement of bottles between stations. These systems reduce the need for manual labor and ensure that materials are consistently delivered to the right location at the right time.

Data Integration

Integrating all your production systems into one centralized platform allows for real-time data sharing. This integration improves decision-making, enhances communication between departments, and ensures consistency in production.

Machine Learning Algorithms

Machine learning algorithms can be implemented as part of an integrated system to automatically adjust filling parameters based on real-time data. These algorithms can analyze historical production data and predict optimal filling speeds, ensuring that accuracy and efficiency are continually optimized.

Boost Speed and Accuracy With Our Pharmaceutical Bottle Filling Machines

Ascend Packaging offers cutting-edge pharmaceutical bottle filling machines designed to boost speed and accuracy in your production process. Our Tomcat 1200 and Tomcat 1210 pharmaceutical bottle filling machines are designed to enhance speed and accuracy in production. The Tomcat 1200 delivers high-speed, precise filling with minimal product waste, ideal for high-volume runs, while the Tomcat 1210 takes accuracy a step further with advanced features like reject sensors and smooth feeding, ensuring each bottle meets exact specifications. Together, these machines streamline operations, reduce downtime, and guarantee compliance, making them the perfect solution for pharmaceutical manufacturers looking to improve efficiency without compromising quality. Contact us today to learn more about our Tomcat machines.

Share This Post

More Like This

https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-01-28 21:13:24How Automated Bottle Count Verification Systems Improve Line Efficiency

https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-01-28 21:13:24How Automated Bottle Count Verification Systems Improve Line Efficiency https://ascendpkg.com/wp-content/uploads/2025/08/Medicine-bottles-being-filled-on-assembly-line-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:49:262026-01-28 21:13:24Pharmaceutical Bottle Filling: How to Prevent Underfilling and Overfilling

https://ascendpkg.com/wp-content/uploads/2025/08/Medicine-bottles-being-filled-on-assembly-line-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:49:262026-01-28 21:13:24Pharmaceutical Bottle Filling: How to Prevent Underfilling and Overfilling https://ascendpkg.com/wp-content/uploads/2025/05/Bottles-being-filled-in-groups-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:31:422026-01-28 21:13:25How Bottle Filling Automation Reduces Downtime

https://ascendpkg.com/wp-content/uploads/2025/05/Bottles-being-filled-in-groups-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:31:422026-01-28 21:13:25How Bottle Filling Automation Reduces Downtime https://ascendpkg.com/wp-content/uploads/2025/05/Medicine-bottles-being-filled-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:18:272026-01-28 21:13:25How to Scale Your Bottle Filling Equipment

https://ascendpkg.com/wp-content/uploads/2025/05/Medicine-bottles-being-filled-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:18:272026-01-28 21:13:25How to Scale Your Bottle Filling Equipment  https://ascendpkg.com/wp-content/uploads/2020/06/Thomas-Packaging-Bottle-Filler-Manifolds-01.jpg

768

1024

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-06 16:36:402026-01-28 21:13:26Explaining Bottle-Filling Manifolds

https://ascendpkg.com/wp-content/uploads/2020/06/Thomas-Packaging-Bottle-Filler-Manifolds-01.jpg

768

1024

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-06 16:36:402026-01-28 21:13:26Explaining Bottle-Filling Manifolds https://ascendpkg.com/wp-content/uploads/2025/03/Factory-filling-medical-bottles.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-03-28 20:29:522026-01-28 21:13:26How to Prevent Cross-Contamination in Pharmaceutical Bottle Filling

https://ascendpkg.com/wp-content/uploads/2025/03/Factory-filling-medical-bottles.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-03-28 20:29:522026-01-28 21:13:26How to Prevent Cross-Contamination in Pharmaceutical Bottle Filling https://ascendpkg.com/wp-content/uploads/2025/02/packets-of-desiccant-scattered-on-a-dark-surface.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-02-25 21:15:252026-01-28 21:13:26Choosing the Right Type of Desiccant for Pharmaceutical Packaging

https://ascendpkg.com/wp-content/uploads/2025/02/packets-of-desiccant-scattered-on-a-dark-surface.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-02-25 21:15:252026-01-28 21:13:26Choosing the Right Type of Desiccant for Pharmaceutical Packaging https://ascendpkg.com/wp-content/uploads/2024/10/medicine-pills-are-filling-in-the-plastic-bottle-on-production-line-machine.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2024-10-29 19:26:352026-01-28 21:13:28Ensuring Compliance With Your Pharmaceutical Bottle Filling Machine

https://ascendpkg.com/wp-content/uploads/2024/10/medicine-pills-are-filling-in-the-plastic-bottle-on-production-line-machine.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2024-10-29 19:26:352026-01-28 21:13:28Ensuring Compliance With Your Pharmaceutical Bottle Filling Machine https://ascendpkg.com/wp-content/uploads/2024/10/Silica-Gel-Desiccant-canister.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2024-10-07 17:28:092026-01-28 21:13:29The Importance of Desiccant Canisters in the Pharmaceutical Industry

https://ascendpkg.com/wp-content/uploads/2024/10/Silica-Gel-Desiccant-canister.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2024-10-07 17:28:092026-01-28 21:13:29The Importance of Desiccant Canisters in the Pharmaceutical IndustryAbout Us

Contact Us

Ascend Packaging Systems LLC.

2222 Hammond Drive

Schaumburg, IL 60173