How Tablet Counting Machines Work

Tablet counting machines automate the process of counting and packaging tablets and capsules accurately.

Tablet counting machines automate the process of counting and packaging tablets and capsules accurately.

Read on to learn more about how different types of tablet counting machines work.

A tablet counting machine is a piece of equipment used in pharmaceutical and related industries to count and package tablets or capsules accurately and efficiently. Pharmacy tablet counting machines are designed to handle large volumes of tablets and ensure precise counting to meet quality and regulatory standards.

Tablet counting machines are typically categorized into three levels of automation:

Let’s break down how each type of counting machine works.

Manual tablet counters require careful attention and dexterity from the operator to ensure accurate counting. While they may be slower than automated counters, manual counters are still widely used in small-scale operations or in situations where automation is not feasible or cost-effective.

Here’s how a manual tablet counter with holes typically works:

The first step in the operation of a manual tablet counting machine is loading the tablets onto a flat tray. The operator manually pours a bulk quantity of tablets onto the flat tray or platform of the tablet counting machine. The tray typically has a smooth, flat surface that provides a visible area for the tablets to be spread out evenly.

After loading the tablets onto the flat tray, the operator uses a shaking motion to encourage the tablets to settle into the small holes or openings on the tray.

After the tablets settle into the holes, the operator continues shaking the tray to remove any excess tablets on the surface.

Once the tablets settle into the holes on the tray and excess tablets are removed, the operator releases the tablets from the holes and guides them into a chute.

In the final step of operating a manual tablet counting machine, the operator completes the counting process by dispensing the tablets into a waiting bottle. Tilting the tray allows the tablets to slide down the chute and into the waiting bottle, completing the manual tablet counting process.

Find out how your packaging business can benefit from a deblisteringmachine.

For a semi-automatic tablet counting machine, the process combines manual and automated elements to optimize accuracy and efficiency.

Here’s a breakdown of how a semi-automatic tablet counting machine typically works:

In the first step of operating a semi-automatic tablet counting machine, tablets are manually loaded into a specially designed feeding hopper.

Tablets from the feeding hopper are directed onto a turntable. This is a rotating platform that efficiently carries the tablets through the counting process. The turntable is equipped with a photoelectric sensor that detects each tablet as it passes by for precise tracking.

In the third step of operating a semi-automatic tablet counting machine, tablets from the turntable are transferred to individual discharge funnels positioned around the turntable. By transferring tablets to individual discharge funnels and using sensors for precise detection, a semi-automatic tablet counting machine ensures accurate tablet counting and efficient movement towards packaging stations.

Lastly, tablets gathered in the discharge funnels are counted before being bottled. By accurately counting tablets and bottling them into waiting containers, this step in operating a semi-automatic tablet counting machine ensures precise tablet counts and efficient packaging for distribution or further processing.

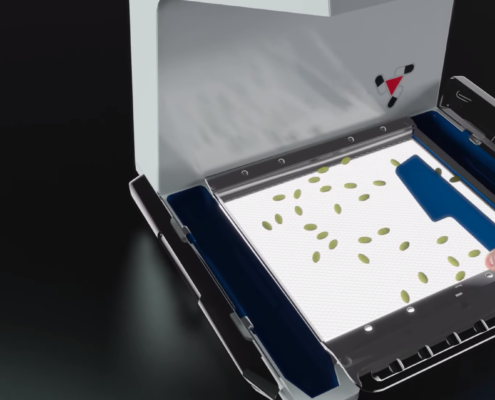

Automatic tablet counting machines are sophisticated devices that handle large-scale production with minimal human intervention while ensuring high levels of efficiency and accuracy in tablet packaging.

Here’s how automatic tablet counting machines work:

Tablets are loaded into the feeding hopper with a vibrating mechanism for efficient feeding, and the automatic tablet counting machine ensures a steady supply of tablets for accurate counting.

Tablets are transitioned from the feeding hopper to multiple-channel vibratory plates with rhythmic vibrations for separation and alignment. The automatic tablet counting machine prepares tablets for precise counting in subsequent stages of the process.

In the third step of operating an automatic tablet counting machine, tablets separated and aligned on the multiple-channel vibratory plates are guided towards the discharge chute for further processing.

With sensor heads that accurately count tablets as they cascade down the discharge chute, the automatic tablet counting machine ensures precise counting and dispensing into packaging containers for distribution or further processing.

Tablets are released into bottles that are then transferred via a conveyor system. This final step of operating an automatic tablet counting machine ensures precise tablet filling and contributes to a seamless workflow.

Overall, tablet counting machines are better in terms of efficiency, accuracy, and consistency compared to manual counting methods.

Ascend Packaging provides a variety of packaging equipment, including automatic and semi-automatic solutions. Our customers can choose the type of equipment that best fits their production requirements, level of automation, and budget. Contact us today to learn more about our selection of tablet counting machines.

https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-02-28 21:12:03How Automated Bottle Count Verification Systems Improve Line Efficiency

https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-02-28 21:12:03How Automated Bottle Count Verification Systems Improve Line Efficiency https://ascendpkg.com/wp-content/uploads/2025/08/Medicine-bottles-being-filled-on-assembly-line-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:49:262026-02-28 21:12:03Pharmaceutical Bottle Filling: How to Prevent Underfilling and Overfilling

https://ascendpkg.com/wp-content/uploads/2025/08/Medicine-bottles-being-filled-on-assembly-line-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:49:262026-02-28 21:12:03Pharmaceutical Bottle Filling: How to Prevent Underfilling and Overfilling https://ascendpkg.com/wp-content/uploads/2025/05/Bottles-being-filled-in-groups-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:31:422026-02-28 21:12:06How Bottle Filling Automation Reduces Downtime

https://ascendpkg.com/wp-content/uploads/2025/05/Bottles-being-filled-in-groups-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:31:422026-02-28 21:12:06How Bottle Filling Automation Reduces Downtime https://ascendpkg.com/wp-content/uploads/2025/05/Medicine-bottles-being-filled-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:18:272026-02-28 21:12:07How to Scale Your Bottle Filling Equipment

https://ascendpkg.com/wp-content/uploads/2025/05/Medicine-bottles-being-filled-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:18:272026-02-28 21:12:07How to Scale Your Bottle Filling Equipment  https://ascendpkg.com/wp-content/uploads/2020/06/Thomas-Packaging-Bottle-Filler-Manifolds-01.jpg

768

1024

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-06 16:36:402026-02-28 21:12:07Explaining Bottle-Filling Manifolds

https://ascendpkg.com/wp-content/uploads/2020/06/Thomas-Packaging-Bottle-Filler-Manifolds-01.jpg

768

1024

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-06 16:36:402026-02-28 21:12:07Explaining Bottle-Filling Manifolds https://ascendpkg.com/wp-content/uploads/2025/03/Factory-filling-medical-bottles.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-03-28 20:29:522026-02-28 21:12:09How to Prevent Cross-Contamination in Pharmaceutical Bottle Filling

https://ascendpkg.com/wp-content/uploads/2025/03/Factory-filling-medical-bottles.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-03-28 20:29:522026-02-28 21:12:09How to Prevent Cross-Contamination in Pharmaceutical Bottle Filling https://ascendpkg.com/wp-content/uploads/2025/02/packets-of-desiccant-scattered-on-a-dark-surface.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-02-25 21:15:252026-02-28 21:12:10Choosing the Right Type of Desiccant for Pharmaceutical Packaging

https://ascendpkg.com/wp-content/uploads/2025/02/packets-of-desiccant-scattered-on-a-dark-surface.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-02-25 21:15:252026-02-28 21:12:10Choosing the Right Type of Desiccant for Pharmaceutical Packaging https://ascendpkg.com/wp-content/uploads/2025/01/How-to-Increase-Pharmaceutical-Bottle-Filling-Speed-and-Accuracy.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-01-13 21:05:042026-02-28 21:12:12How to Increase Pharmaceutical Bottle Filling Speed and Accuracy

https://ascendpkg.com/wp-content/uploads/2025/01/How-to-Increase-Pharmaceutical-Bottle-Filling-Speed-and-Accuracy.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-01-13 21:05:042026-02-28 21:12:12How to Increase Pharmaceutical Bottle Filling Speed and Accuracy https://ascendpkg.com/wp-content/uploads/2024/10/medicine-pills-are-filling-in-the-plastic-bottle-on-production-line-machine.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2024-10-29 19:26:352026-02-28 21:12:14Ensuring Compliance With Your Pharmaceutical Bottle Filling Machine

https://ascendpkg.com/wp-content/uploads/2024/10/medicine-pills-are-filling-in-the-plastic-bottle-on-production-line-machine.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2024-10-29 19:26:352026-02-28 21:12:14Ensuring Compliance With Your Pharmaceutical Bottle Filling MachineAscend Packaging Systems LLC.

2222 Hammond Drive

Schaumburg, IL 60173

Comparing Blister Packaging & Strip Packaging

Comparing Blister Packaging & Strip Packaging This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

AcceptLearn moreWe may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds: