https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-02-27 21:10:40How Automated Bottle Count Verification Systems Improve Line Efficiency

https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-02-27 21:10:40How Automated Bottle Count Verification Systems Improve Line EfficiencyA Guide to Bottle-Filling Manifolds

In the fast-evolving world of pharmaceutical and liquid packaging, precision and efficiency aren’t just goals—they’re requirements. One critical component that helps meet these standards is the bottle-filling manifold.

Whether you’re upgrading existing lines or investing in new technology, understanding how manifolds work, their benefits, and how to maintain them can be a game-changer for your operation. These systems are essential not only for boosting productivity but also for upholding quality assurance standards across a range of industries beyond pharmaceuticals.

What Is a Bottle-Filling Manifold?

A bottle-filling manifold is a fluid distribution system designed to channel liquid into multiple bottles simultaneously. It consists of controlled flow paths that enable smooth, even dispensing of liquid into containers. In high-speed, high-volume pharmaceutical environments, this kind of precision is not just advantageous—it’s essential.

Though the term “manifold” might seem technical, its role is simple: to ensure consistent dosing across all fill heads. This optimization boosts production rates and reduces waste. In pharmaceutical bottle filling, this consistency is vital for meeting regulatory standards and maintaining product integrity. Manifolds also manage critical liquid attributes, such as viscosity, temperature, and flow rate, to ensure a stable, reliable packaging process.

How Bottle-Filling Manifolds Work in Automated Systems

Modern filling systems incorporate bottle-filling manifolds into automated machines. These systems control liquid flow using a network of valves and channels that direct fluid from the reservoir to the filling nozzles. This guarantees that each bottle receives the same amount of liquid, ensuring uniformity across every batch.

Types of Bottle-Filling Manifolds

When selecting a bottle-filling manifold, it’s important to understand the two primary design categories available. Each type serves specific operational needs, hygiene requirements, and production scales.

Below, we explore the two main types of manifolds used in today’s automated liquid filling systems.

Single-Use Manifolds

Single-use systems are pre-assembled and sterilized components engineered for one-time use. They are ideal for high-purity applications where avoiding cross-contamination is critical. These systems are commonly used in pharmaceutical environments for clinical trials or products that require absolute sterility.

One of their primary advantages is that they significantly reduce cleaning time and validation requirements, making them perfect for operations with frequent product changeovers. By eliminating the risk of residue buildup and contamination, single-use systems help ensure regulatory compliance while speeding up production transitions.

Clean-in-Place (CIP) Manifolds

CIP systems are reusable and integrate directly with cleaning systems, enabling sanitation without disassembly. They’re sustainable and cost-effective for continuous, large-scale operations. By minimizing labor and ramp-up time, they help manufacturers meet stringent hygiene standards efficiently.

Automation takes manifold functionality a step further by synchronizing liquid flow with machine operations, reducing manual tasks and potential errors. Integrated SCADA and smart platforms provide real-time monitoring, predictive maintenance, and automated alerts.

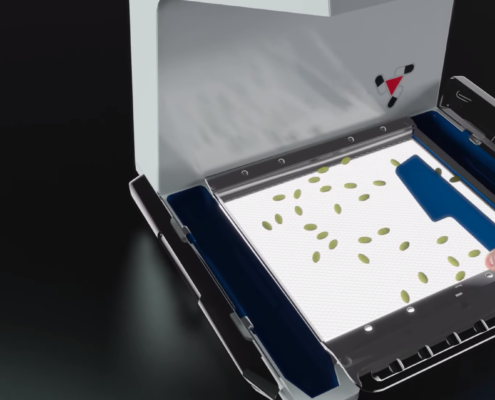

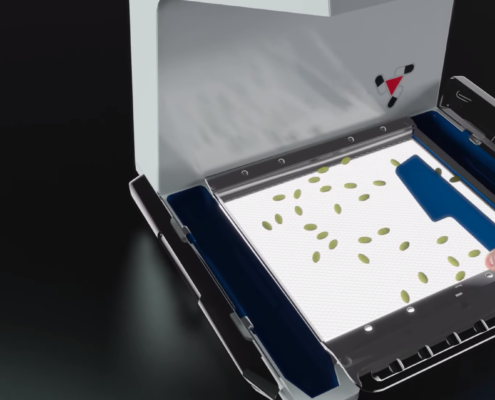

Pharmaceutical manufacturer GSK was faced with a unique bottle-filling challenge with Tums Chewy Bites tablets. Ascend Packaging came to the rescue.

Benefits of Well-Engineered Filling Systems

When properly designed, bottle-filling manifolds elevate the performance of any liquid-filling system.

Benefits include:

Product Accuracy

Engineered for precise dosing, manifolds reduce waste and ensure regulatory compliance. This high level of accuracy maintains product consistency and protects brand integrity.

Reduced Downtime

Efficient cleaning and quick changeovers decrease production halts. Preventive maintenance further minimizes unexpected repairs, keeping operations on schedule.

Simplified Sanitation

Whether CIP or single-use, manifolds make cleaning easy. This reduces contamination risk and helps maintain strict hygiene standards while boosting team productivity.

Regulatory Compliance

Pharmaceutical-grade materials like stainless steel or medical polymers ensure manifolds meet FDA and GMP requirements, preparing systems for global distribution.

Operational Flexibility

Manifolds adapt to different liquids and container types, offering scalability without the need for significant retooling.

Design Innovations Since 2022

Bottle-filling manifold technology continues to evolve. Since 2022, notable advancements include:

Advanced Materials

New polymers and stainless alloys improve durability, expand chemical compatibility, and offer resistance to harsh cleaning agents, all while meeting biocompatibility standards.

Modular Architecture

Modular manifolds support quick configuration changes, which is ideal for manufacturers handling multiple SKUs. This boosts adaptability without compromising system efficiency.

Smart Integration

Modern manifolds now feature plug-and-play integration with Industry 4.0 systems. Built-in sensors and automation tools enable predictive maintenance, real-time data collection, and performance optimization.

Maintenance and Troubleshooting Tips

Regular maintenance keeps manifolds running smoothly. Here’s how to spot and resolve common issues:

Common Wear Points

Seals, valve seats, gaskets, and O-rings are most susceptible to wear. Check these routinely, especially when handling viscous or abrasive fluids.

Leak Detection

Watch for uneven fills or drips. Use pressure tests and visual inspections to detect leaks early, minimizing product loss and contamination risks.

Irregular Fill Rates

This can indicate clogging, air entrapment, or degraded internal components. Cleaning or replacing parts typically resolves the issue. Advanced systems may flag these problems before they affect output.

When to Replace

If persistent problems continue despite maintenance, a manifold upgrade may be necessary. Proactive replacement prevents downtime and safeguards product quality.

Record Keeping

Maintaining a detailed log of maintenance, inspections, and replacements helps track system performance and supports audit readiness.

Selecting the Right System

To choose the best system, consider the following factors:

- Liquid Properties: Match the design to the liquid’s viscosity, temperature, and chemical makeup.

- Production Scale: High-volume lines benefit from CIP manifolds, which offer lower downtime and greater throughput.

- Compliance Requirements: Use FDA- and GMP-certified materials to simplify audits and reduce compliance risk.

- System Compatibility: Ensure the manifold fits seamlessly with your existing bottle-filling equipment.

- Scalability: Opt for modular systems if you’re planning to expand operations or introduce new product lines.

Integration With Existing Equipment

One of the most important aspects of selecting a bottle-filling manifold is its ability to integrate seamlessly into your current production environment. Whether you are operating rotary fillers, inline systems, or customized equipment, today’s manifolds are engineered for adaptability.

Integration typically begins with an evaluation of your existing equipment setup to ensure mechanical and control system compatibility. Manifolds must align with fill head configurations, pump types, and control protocols. In many cases, adapters and modular connectors are used to bridge existing lines with new manifold technologies.

Moreover, modern manifolds are often designed with universal fittings and programmable logic controller (PLC) compatibility to streamline installation. This enables faster changeovers and real-time system synchronization. Digital integration can also allow manifolds to feed performance data directly into SCADA systems, aiding in overall equipment effectiveness (OEE) tracking and process optimization.

Ensuring seamless integration minimizes downtime during system upgrades, maintains product consistency, and enhances the flexibility of your liquid filling operations.

Frequently Asked Questions

Navigating the nuances of bottle-filling systems can raise a number of operational and strategic questions—especially as technology and compliance standards evolve.

Below are answers to several frequently asked questions that go beyond the basics, providing deeper insights into optimization, integration, and system performance.

How often should bottle-filling manifolds be inspected?

Regular inspections should be scheduled based on production volume and fluid characteristics. For most pharmaceutical applications, a weekly visual inspection and monthly in-depth assessment are recommended.

What role do manifolds play in reducing cross-contamination?

Manifolds, particularly single-use types, help minimize cross-contamination by eliminating the need for cleaning between different product batches. Their design can isolate flow paths, preventing mix-ups and maintaining purity.

Are there cost trade-offs between single-use and CIP systems?

Yes. Single-use systems often have higher recurring costs due to disposability but offer faster changeovers and reduced contamination risk. CIP manifolds require a higher initial investment and rigorous cleaning validation but are more cost-effective over time for large-scale production.

We Design Custom Bottle-Filling Manifolds

At Ascend, we provide high-quality bottle-filling manifolds at a competitive price and with fast lead times. As bottle-filling machine experts, our team customizes your parts based on application specifications. Once we’ve manufactured your custom parts, we ensure they’re successful by testing them before shipping them to your facility. Contact us today for more information on manifolds and bottle-filling equipment that result in increased efficiency, uptime, and quality.

Share This Post

More Like This

https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-02-27 21:10:40How Automated Bottle Count Verification Systems Improve Line Efficiency

https://ascendpkg.com/wp-content/uploads/2020/10/VIVID-Rx-Screenshot-2.png

1080

1920

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:55:532026-02-27 21:10:40How Automated Bottle Count Verification Systems Improve Line Efficiency https://ascendpkg.com/wp-content/uploads/2025/08/Medicine-bottles-being-filled-on-assembly-line-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:49:262026-02-27 21:10:40Pharmaceutical Bottle Filling: How to Prevent Underfilling and Overfilling

https://ascendpkg.com/wp-content/uploads/2025/08/Medicine-bottles-being-filled-on-assembly-line-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-08-14 17:49:262026-02-27 21:10:40Pharmaceutical Bottle Filling: How to Prevent Underfilling and Overfilling https://ascendpkg.com/wp-content/uploads/2025/07/Lower-manifold-system.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-07-25 19:37:392026-02-27 21:10:41A Guide to Lower Manifolds for Bottle Filling Equipment

https://ascendpkg.com/wp-content/uploads/2025/07/Lower-manifold-system.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-07-25 19:37:392026-02-27 21:10:41A Guide to Lower Manifolds for Bottle Filling Equipment  https://ascendpkg.com/wp-content/uploads/2025/05/Bottles-being-filled-in-groups-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:31:422026-02-27 21:10:43How Bottle Filling Automation Reduces Downtime

https://ascendpkg.com/wp-content/uploads/2025/05/Bottles-being-filled-in-groups-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:31:422026-02-27 21:10:43How Bottle Filling Automation Reduces Downtime https://ascendpkg.com/wp-content/uploads/2025/05/Medicine-bottles-being-filled-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:18:272026-02-27 21:10:44How to Scale Your Bottle Filling Equipment

https://ascendpkg.com/wp-content/uploads/2025/05/Medicine-bottles-being-filled-in-factory.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-05-28 21:18:272026-02-27 21:10:44How to Scale Your Bottle Filling Equipment  https://ascendpkg.com/wp-content/uploads/2025/03/Factory-filling-medical-bottles.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-03-28 20:29:522026-02-27 21:10:46How to Prevent Cross-Contamination in Pharmaceutical Bottle Filling

https://ascendpkg.com/wp-content/uploads/2025/03/Factory-filling-medical-bottles.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-03-28 20:29:522026-02-27 21:10:46How to Prevent Cross-Contamination in Pharmaceutical Bottle Filling https://ascendpkg.com/wp-content/uploads/2025/02/packets-of-desiccant-scattered-on-a-dark-surface.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-02-25 21:15:252026-02-27 21:10:47Choosing the Right Type of Desiccant for Pharmaceutical Packaging

https://ascendpkg.com/wp-content/uploads/2025/02/packets-of-desiccant-scattered-on-a-dark-surface.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-02-25 21:15:252026-02-27 21:10:47Choosing the Right Type of Desiccant for Pharmaceutical Packaging https://ascendpkg.com/wp-content/uploads/2025/01/How-to-Increase-Pharmaceutical-Bottle-Filling-Speed-and-Accuracy.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-01-13 21:05:042026-02-27 21:10:49How to Increase Pharmaceutical Bottle Filling Speed and Accuracy

https://ascendpkg.com/wp-content/uploads/2025/01/How-to-Increase-Pharmaceutical-Bottle-Filling-Speed-and-Accuracy.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2025-01-13 21:05:042026-02-27 21:10:49How to Increase Pharmaceutical Bottle Filling Speed and Accuracy https://ascendpkg.com/wp-content/uploads/2024/10/medicine-pills-are-filling-in-the-plastic-bottle-on-production-line-machine.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2024-10-29 19:26:352026-02-27 21:10:51Ensuring Compliance With Your Pharmaceutical Bottle Filling Machine

https://ascendpkg.com/wp-content/uploads/2024/10/medicine-pills-are-filling-in-the-plastic-bottle-on-production-line-machine.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2021/09/Ascend-Logo-Blue_0001_Blue-Ascend-Logo-300x108.png

AbstraktMarketing2024-10-29 19:26:352026-02-27 21:10:51Ensuring Compliance With Your Pharmaceutical Bottle Filling MachineAbout Us

Contact Us

Ascend Packaging Systems LLC.

2222 Hammond Drive

Schaumburg, IL 60173