Manufacturing high-quality blister packaging for your products starts with utilizing precision-machined custom tooling. Ascend Packaging Systems explains the importance of customizing your packaging tools to guarantee quality assurance and compliance.

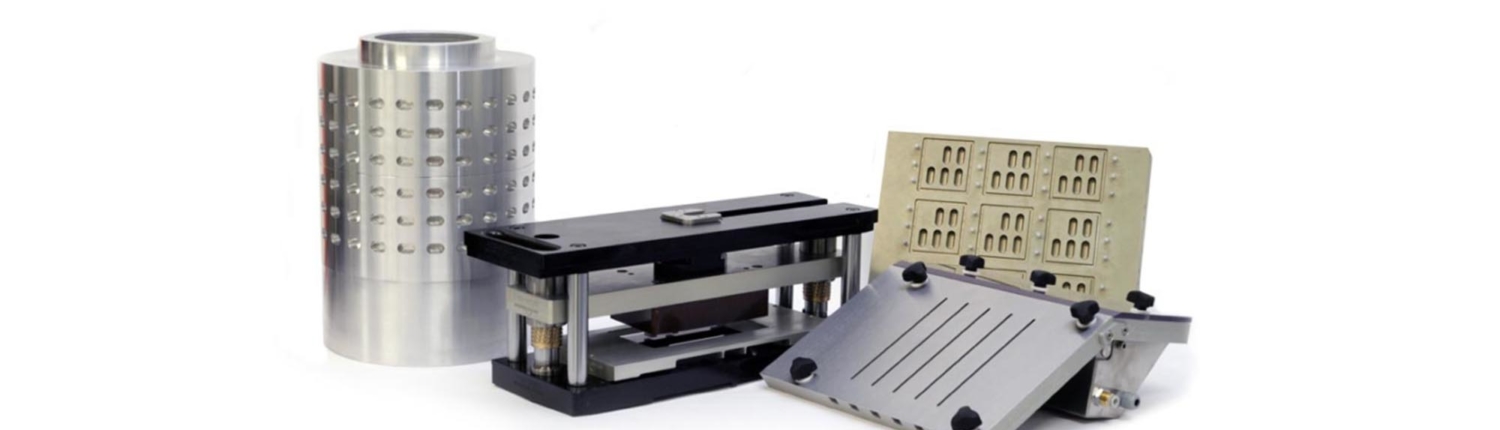

Blister Packaging Tooling

Using custom tooling that’s compatible with your blister packaging machine is crucial. When you have the right tooling and parts in place, your packaging equipment performs at maximum efficiency, reduces downtime, and produces quality packaging.

Essential tooling that you can tailor to your machining needs include:

- Form dies

- Seal dies

- Guide tracks

- Die cutters

- Perf dies

There are a variety of custom tooling and change parts that are compatible with nearly all industry makes and models, including manufacturers such as Uhlmann, MAC, Klockner, Noack, Ministar, IWKA, Blipack, IMA, Bosch, and CAM.

Packaging Machines and Tooling

A wide range of packaging machines are compatible with customized tooling:

Automated Packaging Machines

If you have small- or medium-scale packaging needs, automated packaging machines equipped with custom tooling systems ensure an efficient, continuous production process. With the right tooling, your automated machine can produce blister packaging batches of up to 10,000 packs.

Ascend Packaging has invested more than 50 years in providing high-quality blister machine tooling and change parts for nearly all makes and models in the industry.

Semi-Automatic Packaging Machines

Adding custom tooling to your semi-automatic packaging machine can boost your packaging process for tablets, capsules, sachets, and pouches. Some semi-automatic machine models don’t require tool-up, set up, or cleaning when switching from large-scale packaging to small-scale production.

The Custom Tool and Design Process: Packaging Compliance

The custom tool design process also ensures that your blister packaging is FDA compliant.

The FDA packaging compliance requirements state that a controlled substance that has any preparation for human use that consists in whole or in part of any substance subject to control under the Comprehensive Drug Abuse Prevention and Control Act of 1970 and that is in dosage form intended for oral administration shall be packaged in accordance with the poison prevention packaging standards.

The compliance blister packs must continue to function with the defined effectiveness specifications when coming in contact with the contained substance. To satisfy this requirement, appropriate scientific evaluations must be conducted to assess the compatibility of the substance with compliance packaging. Our team of engineers can help create package designs implementing the best senior-friendly/child-resistant features based on your specific application.

Ascend Packaging, Your Custom Tooling Company for Blister Packaging Solutions

Ascend doesn’t just provide you with pharmaceutical blister tooling—we deliver a complete blister packaging solution. With over 50 years of experience manufacturing blister packaging tooling, we know the necessary steps to create packages with correct clearances and tolerances and address compliance requirements. Unlike other custom tooling companies, Ascend takes our commitment to customization a step further. An Ascend engineer visits your facility, measures your blister packaging machine, designs custom blister packaging and machine tooling, and follows up by assisting your team with the startup of your new additions. For a quality blister packaging solution that guarantees quality assurance, contact Ascend today.

About Us

Contact Us

Ascend Packaging Systems LLC.

2222 Hammond Drive

Schaumburg, IL 60173